Cutting-edge technology

Create first-class products

Create first-class products

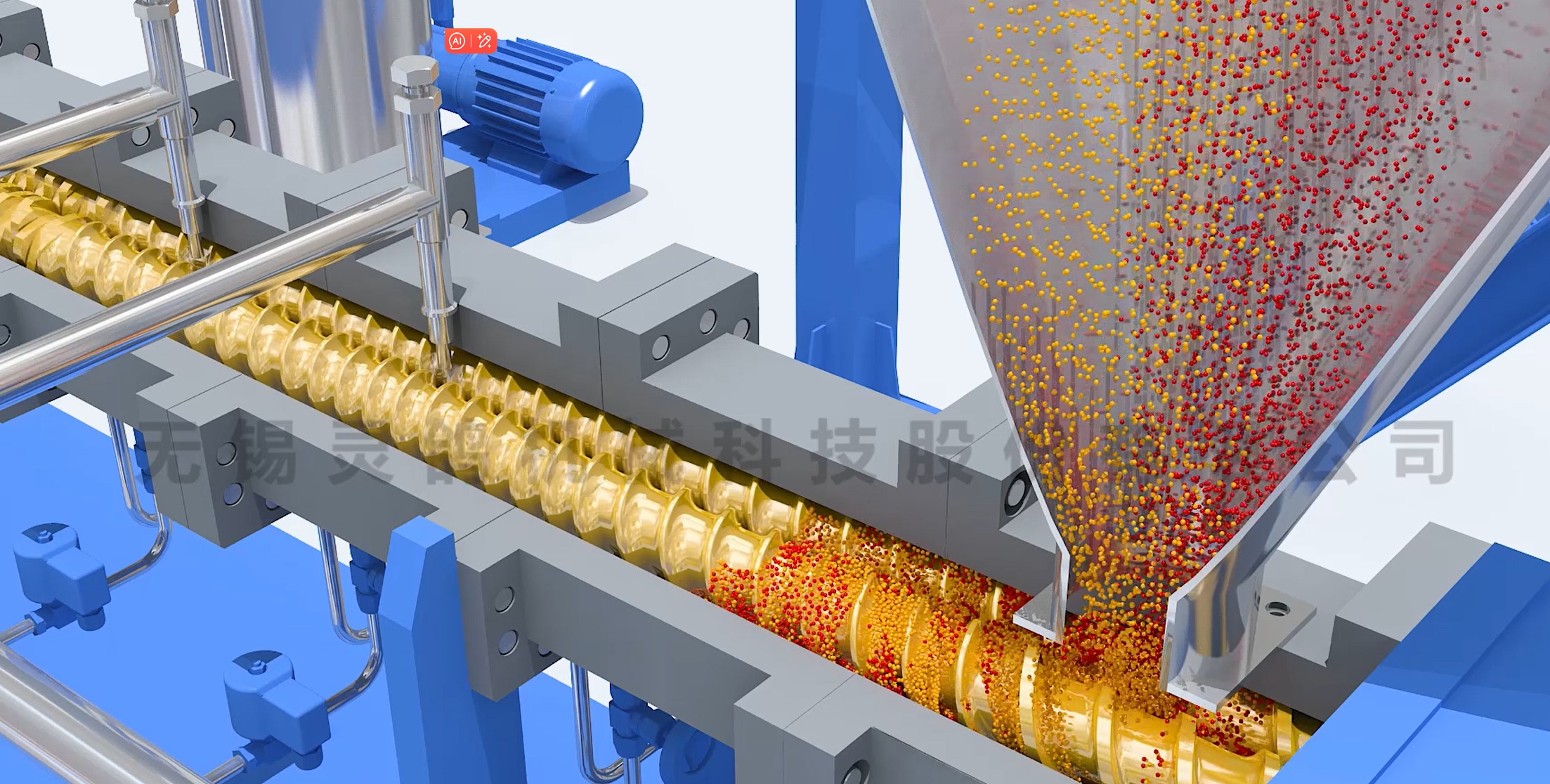

We have a complete integrated system and processing technology, can provide customers with a full process integration technology package for automatic feeding, formulation mixing and bulk material automatic processing of the whole process. From consulting, design, process, optimization, production, transportation, installation, commissioning and operation to global services, Lingge covers all production value-added links.

Company Profile

Company Profile

Development History

Development History

Manufacturing Facilities

Manufacturing Facilities

Credit

Credit

Partners

Partners

Product Center

Product Center

System Center

System Center

Service Innovation

Service Innovation

Technological innovations

Technological innovations

Company News

Company News

Exhibition Info

Exhibition Info

Lingood Technology

Lingood Technology

Customer Cases

Customer Cases

Multimedia Downloads

Multimedia Downloads

Global Network

Global Network

Service Contacts

Service Contacts

Join Us

Join Us

Investor Contact

Investor Contact

General Information

General Information

Company Announcement

Company Announcement